Printing Flexible Filament on the Ender 3

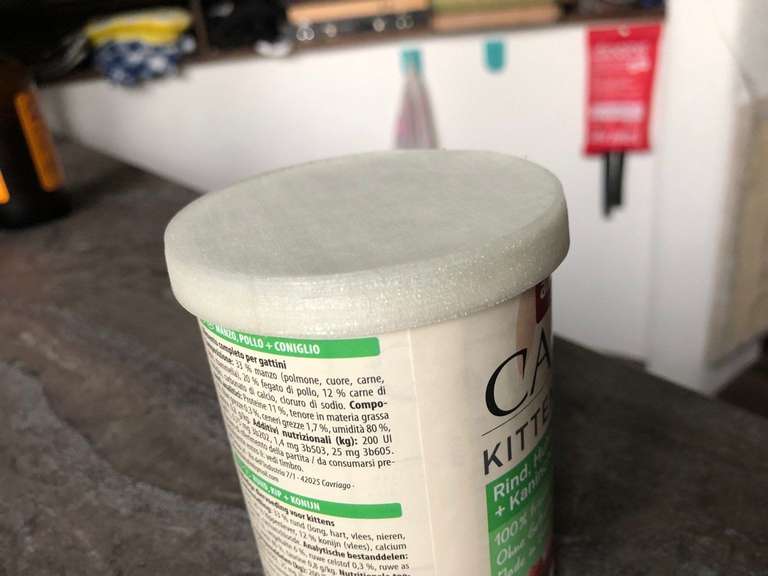

This morning, I decided to 3D print a cover for cat food tin cans, so I could store open cans more elegantly in the fridge. And since I still had some flexible filament lying around, I chose to use that because surely it would be a much better fit if the cover was flexible.

The design only took a few minutes, because it is essentially just a cylinder that is open on one side.

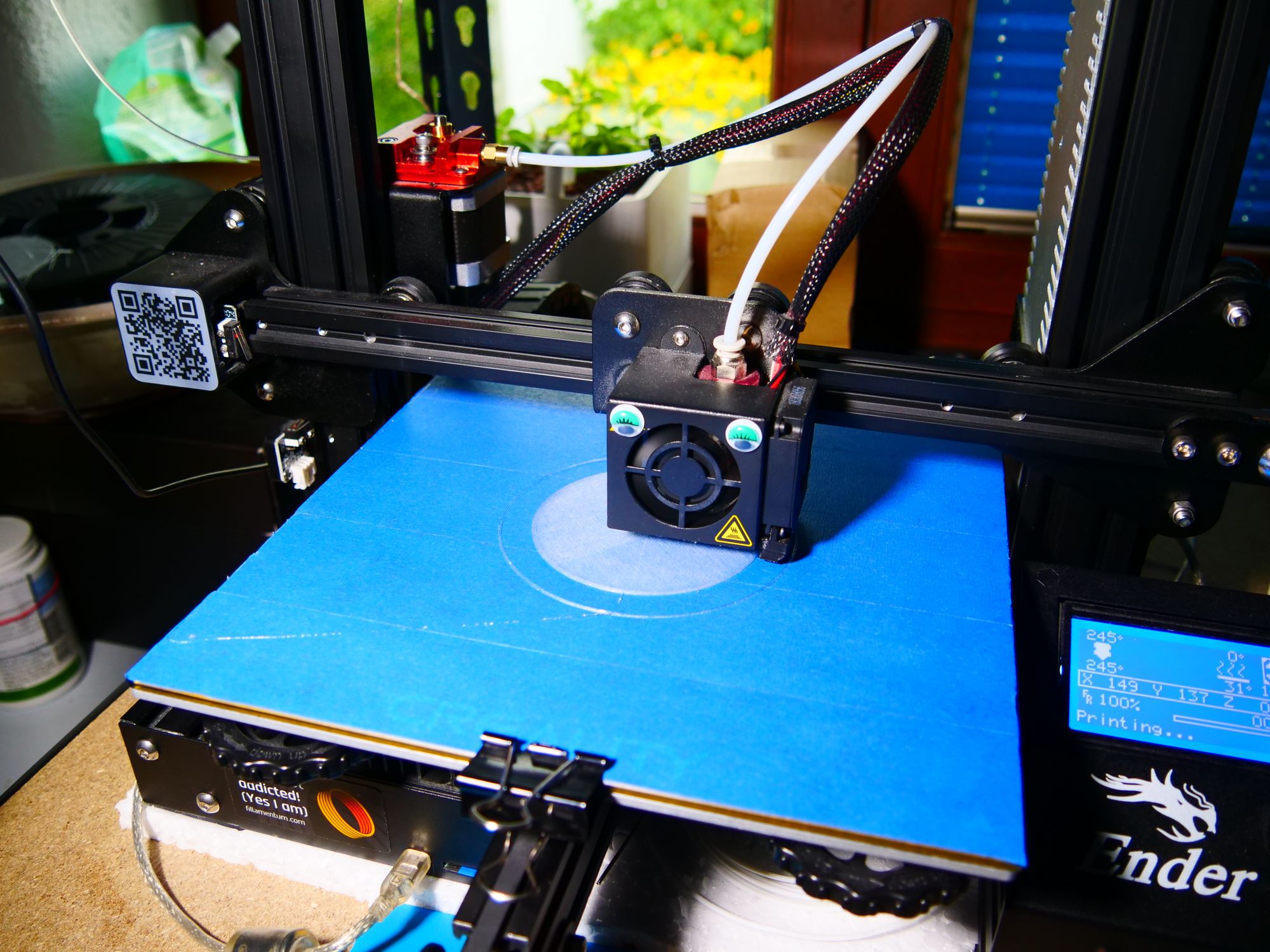

I also had already successfully used the flexible filament with my Ender 3 printer several times before. I still remembered that I needed to disable the filament retraction as this would otherwise cause issues due to the flexibility. I then looked up some further parameters for this material: it needs to be printed fairly hot (between 220°C and 260°C), the build plate should not be heated, it's better to print slowly (to avoid extrusion issues due to the flexibility) and I increased the flow to 120% so I would get nice layers without any gaps (which I remembered happening a lot in previous prints).

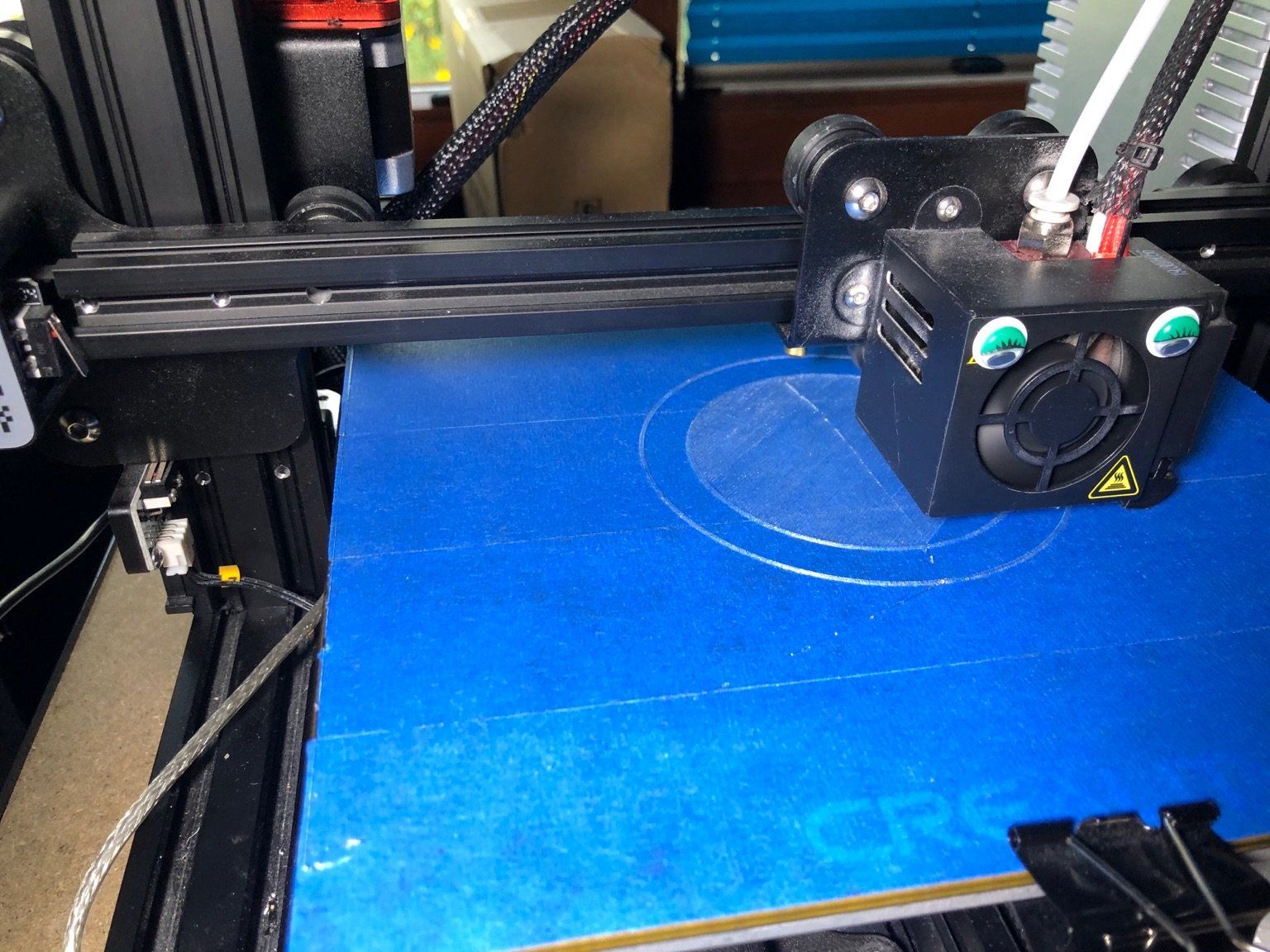

I am also currently testing blue tape on the build plate. My original build plate recently broke and prints tend not to stick too well to the glass plate that I still have. A common tip is to use blue tape; i.e., masking tape for painting. The 3M tape seems to be working well. It actually seems to work pretty well for me, too, as the first layer looked absolutely perfect.

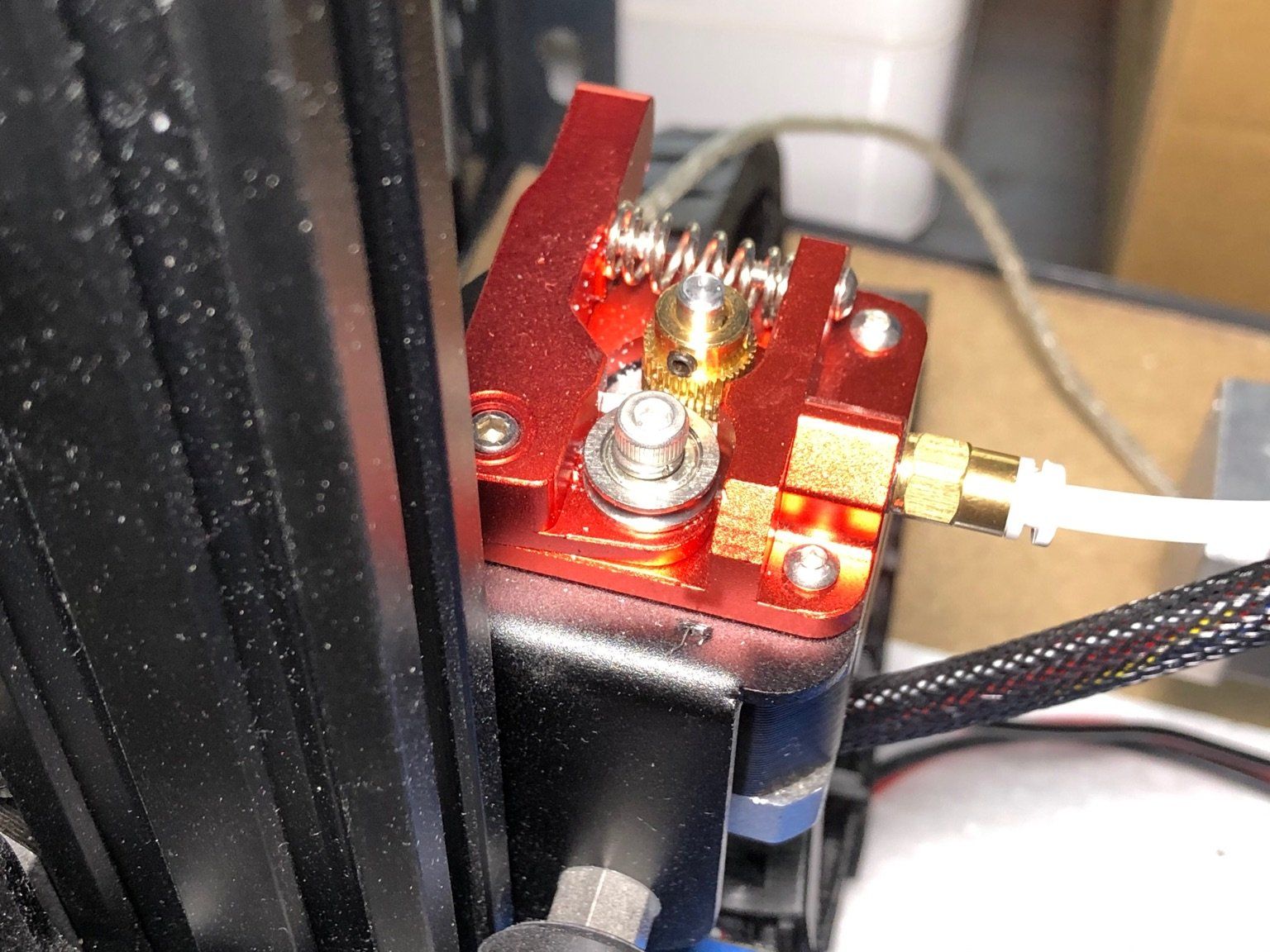

However, when I came back to the printer a few minutes later it was in the middle of the second layer, but hat stopped extruding material. As expected, the filament had tangled up in the extruder. Because the filament is so flexible, it can easily slip out to the top or one of the sides, rather than being pushed into the Bowden tube that transports the filament to the hot end. You can see the problematic spot in the following picture. A brass gear normally pushes the material into the tube on the right, but there is some space before the tube starts, where very flexible material may escape.

Retracting filament during a print frequently causes this issue. But I had disabled filament retraction in the slicer settings. So I double checked my settings and tried again, only to have the same issue. This time I kept an eye on it and saw that there actually was a brief filament retraction during the layer change.

I then spent quite some time looking through all the setting of PrusaSlicer and also trying to download other filament profiles. But nothing helped. I couldn't get rid of the retraction. I am sure it is somehow possible to achieve this, but so far I haven't been able to.

My solution at the moment is to slice models that I want to print with flexible material in Cura rather than PrusaSlicer, as it is very easy to disable retraction in Cura.

The cover came out pretty nicely in the end and it does exactly what it should: covering cans so the cat food smell doesn't end up all over the fridge.

If you're interested, you can download the design on Thingiverse.