Solving 3D Printing Issues

Yesterday, my 3D printer suddenly started to have severe underextrusion issues. After trying many different approaches to solve the problem, I finally have a working 3D printer again.

Yesterday morning, at approximately 9:00, I started a 3D print, that would take about 7 hours to complete. I always check how the first layer comes out, as this is where the most issues become apparent. The first layer was fine; I only noticed a very slight irregularity of the skirt (a printed fence around the print) on the second layer. But the print itself looked okay. Then I left the house for several hours.

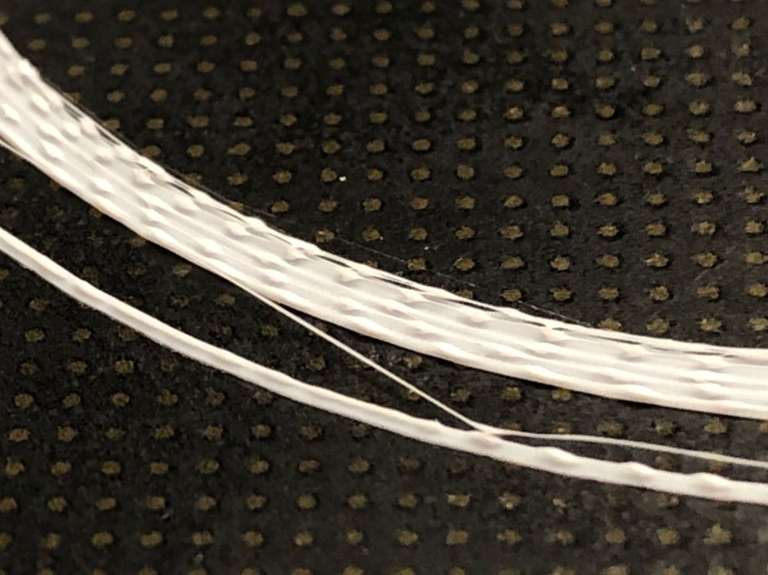

When I returned at about 14:00, the print showed really bad quality. But it was still printing and I decided to let it finish and debug afterwards. However, about 30 minutes later, the print started to show extreme stringing and barely any material was extruded any longer.

So I stopped the print and did several test prints; all with similarly bad results. It was quite hard to get the first layer to stick to the print bed; and when it did, the first layer printed fine, but starting from the second layer, the problems began.

When I started to research 3D printing issues, I quickly realized it had to be severe underextrusion (i.e., way too little material being extruded). Most often, this is due to a clogged nozzle. I had already thought of a clogged nozzle and cleaned it; so it had to be something else.

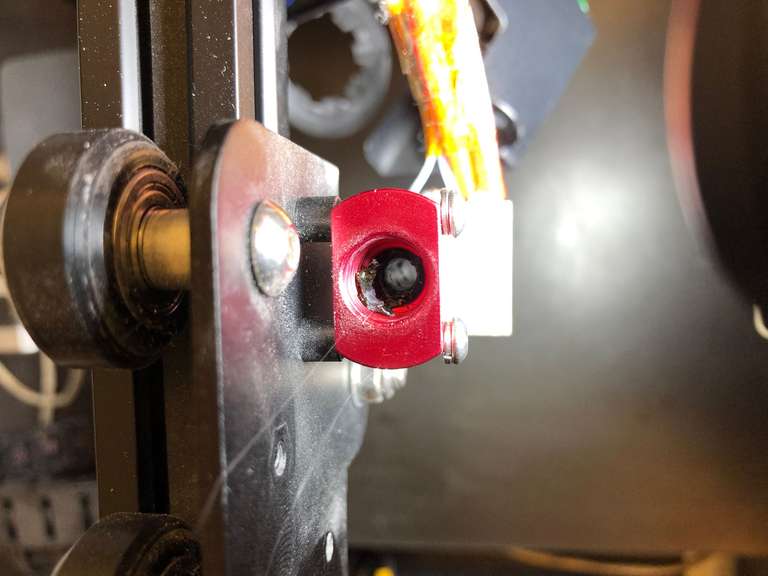

After some time of unsuccessfully trying to find and fix the issue (trying different parameters, like feed rate, temperature and speed), I got frustrated and decided to go play some video games instead. During gaming, I realized it may be an issue with the cogwheel that pushes the filament into the 3D printer. I thought maybe the wheel was worn. But taking the feeder apart and checking, the wheel showed pretty much no wear, except for some color stains.

So I started searching the internet for underextrusion information that was specific to my 3D printer model. And I found this excellent video on the "Tomb of 3D Printed Horrors" YouTube channel (which I highly recommend for their 3D printing advice). By that time it was late and I went to bed.

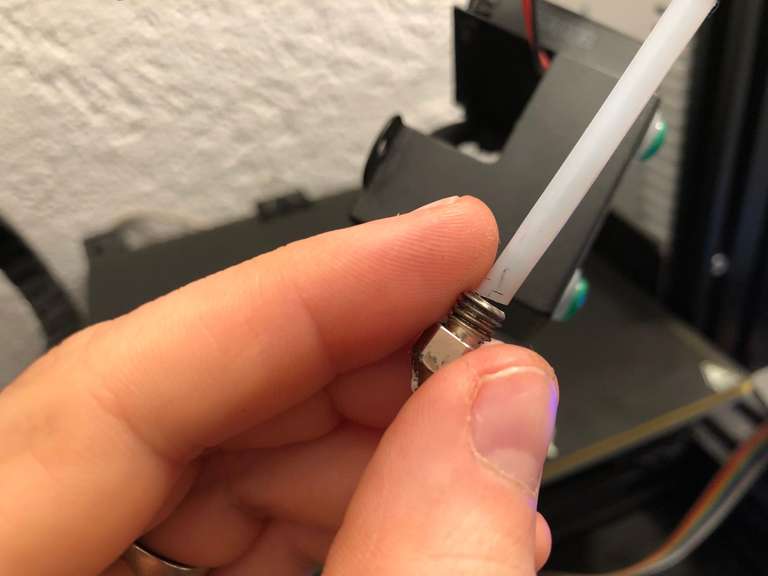

First thing in the morning, I tried the suggested fix of cleaning the hot end and reassembling it, such that the bowden tube sits firm against the nozzle (instead of only cleaning the nozzle itself). My extruder actually had a lot of gunk in it and I was certain that this had been the issue. My bowden tube also turned out to be angled at the end, which prevented a flush fit with the nozzle, so I sanded it down a little.

After re-assembly, I impatiently anticipated the results of the next test print. But, same issue as before 😭

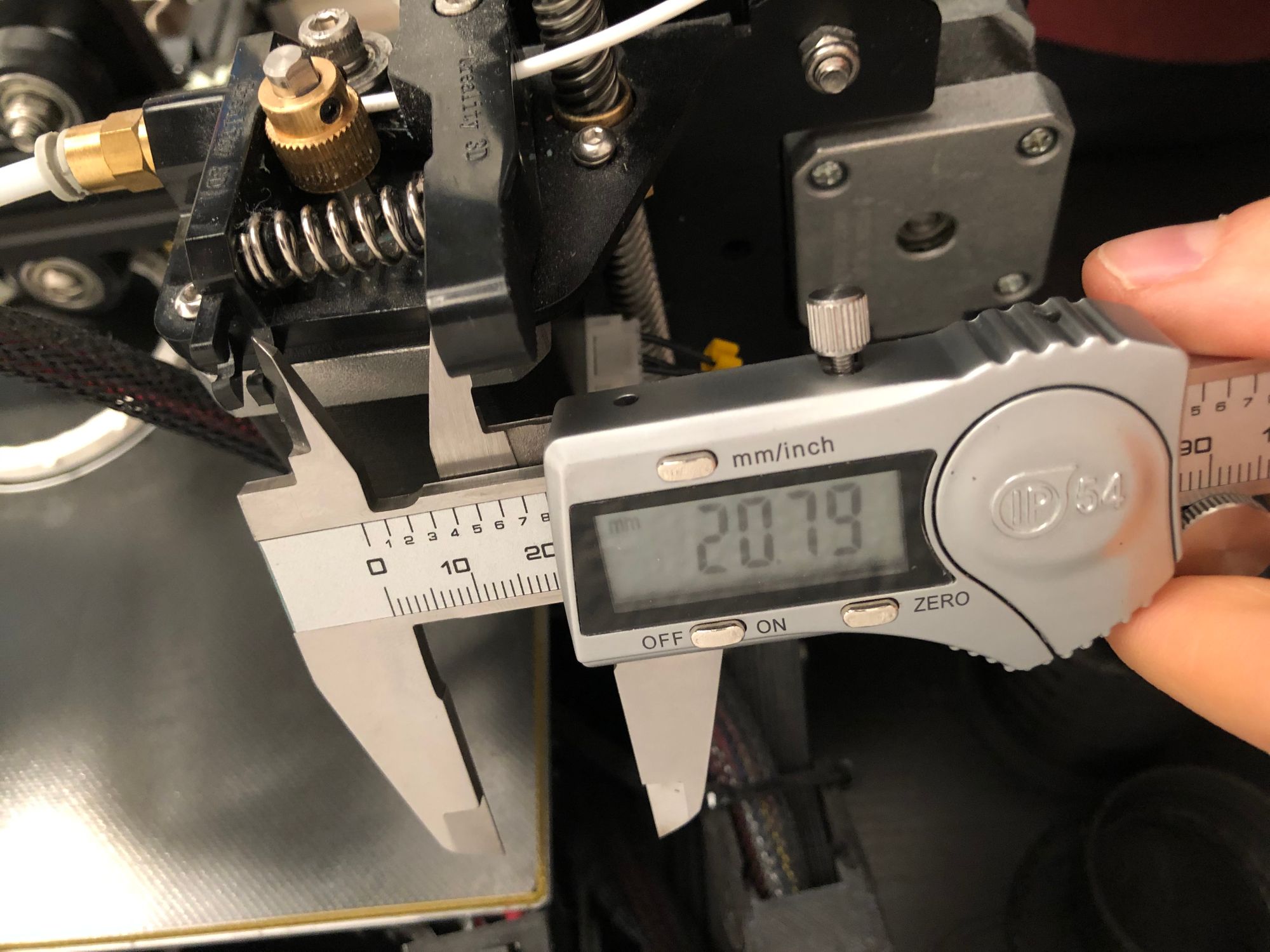

I then switched the nozzle for a new one to make sure it was actually clean. Again, no luck and still bad underextrusion. So I turned my attention back to the extruder feeder. And indeed: when I helped the feeder to push the filament with my hand, the print quality increased.

After playing around with it for a bit, I realized it hadn't been the cogwheel, but the spring that was pushing the wheel against the filament seemed to have lost its strength. Since I couldn't get a replacement on short notice, I started to work on a temporary solution.

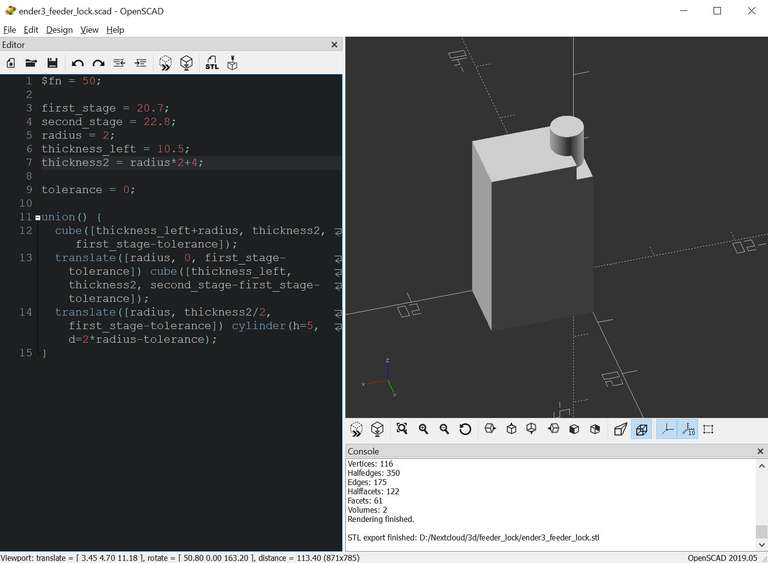

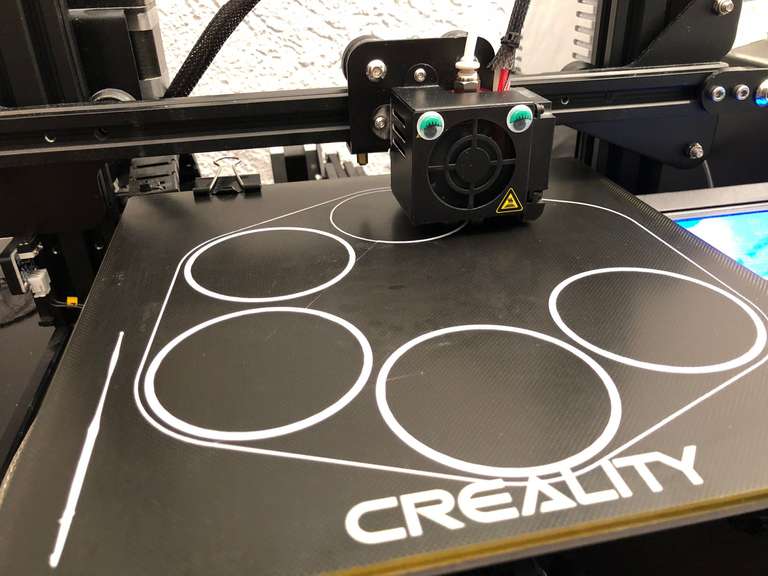

I designed and 3D printed a little wedge to jam in the feeder to help the spring do its work. And finally, this morning at approximately 11:00, my printer was back to successfully producing prints.

By now, I am finally back to happily 3D printing. I had gotten quite frustrated with all of it, but I am happy to have been able to resolve it. And now I know so much more about 3D printing once again.

Yay 🥳 Printing once again.

Update: When I changed the hotend some time later, I actually discovered that there was a crack in the plastic of the extruder ...